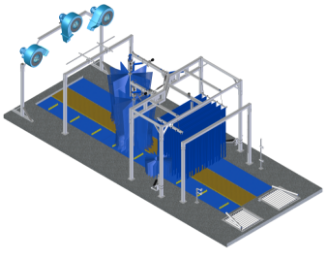

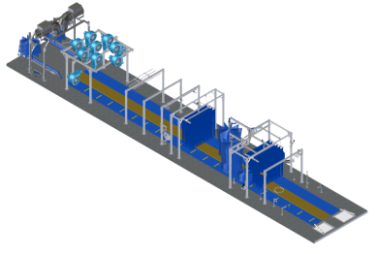

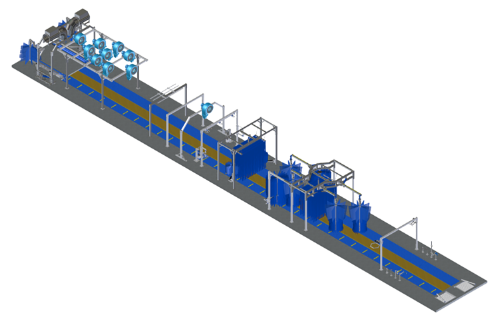

30" and 42 Dual Belt

Eliminates guide rails. Better vehicle control and a wider range of vehicles. Optimal for new construction, frequently retrofitted by widening the pit with equipment in place. A dazzling customer wash experience.

AVW is a leading developer of tunnel systems installed in many of the most successful car washes around the globe. All systems incorporate leading edge technology, high-quality components, and provide reliable operation with minimal maintenance and downtime.

AVW is a family-owned company that builds innovative car washing equipment and long-term mutually beneficial business relationships with our customers. Nearly 50 years of experience and product innovation goes into every piece of equipment we produce. Our flexible manufacturing allows us to easily modify existing components, or design a brand new part. We believe in doing whatever it takes to make sure your facility delivers outstanding washes simply, cost-effectively and reliably, on the day it goes live and for years to come.

1973 AVW Founded

1983 AVW Develops the Circular Motion Mitter

1987 Makes vertical angle of brushes adjustable to vehicle profiles

1992 AVW Invents the modern “Flex Wrap”

1999 Builds the first Detail Belt Conveyor

2000 Fabricates the first Following Wheel Blaster in NA

2002 Licenses and introduces the Kaady Contour Washer

2005 Launches the Belt Conveyor in wet/wash applications

2011 AVW Belt Conveyor builds surpass roller conveyor builds

2014 AVW gets compact vac canister “off the ground”

2016 AVW Automates express detailing of mirrors, windows, and tires with Finishing Module

Our emphasis on make-to-order manufacturing enables us to fabricate your equipment as if you were building it yourself. We use contemporary manufacturing technologies, and our methods consistently deliver quality and precision. We maintain conventional and state-of-the-art fabrication capabilities to provide alternatives; we don’t allow commercially available technology to limit design options and your ideas.

Once again, AVW has applied the Simplicity in Motion design principles to engineer a revolutionary, elegant and low-maintenance conveyor system. Belt Conveyors provide a noticeably superior customer experience — easier to load, smoother, quieter, and safer. They eliminate roller jumps and conveyor damage claims, appeal to owners of low ground clearance exotics, and accommodate dually pickups. Guiderail and trap door issues are a thing of the past, maintenance is drastically reduced, and autonomous braking safety system issues are eliminated without a hitch. And then there’s the processing speed — higher car counts, faster customer service and increased profits. It’s the future of car wash operation.

Eliminates guide rails. Better vehicle control and a wider range of vehicles. Optimal for new construction, frequently retrofitted by widening the pit with equipment in place. A dazzling customer wash experience.

Eliminates guide rails. Better vehicle control and a wider range of vehicles. Optimal for new construction, frequently retrofitted by widening the pit with equipment in place. A dazzling customer wash experience.

AVW tunnel systems put our Simplicity in Motion and manufacturing principles into action. Our tunnel designs cover a wide range of sizes and are fully customizable. From 29’ compact washes to 130’ and even larger full-sized systems, we engineer to site-specific requirements for fleet, in-bay conversion, express, flex-serve, full-serve, and detail tunnels.

Simplicity in Motion design principles inherently produce more durable and reliable components, since there are fewer things to break, wear out, malfunction, and maintain. From a la carte items, all the way through start-to-finish turnkey installations, your equipment will wash high volumes of consistently clean and dry cars.

Stainless Steel. We manufacture nearly all structural and mechanical components using stainless steel. Virtually inert to the harsh conditions found in the carwash environment, stainless steel maintains its structural and aesthetic integrity for decades.

From Seattle to Chicago, Athens to St. Petersburg, Tokyo to Nairobi, and even as far as Melbourne, AVW combines best practices into exceptional designs for world class customer experiences.

We provide assistance and experience early in your project planning phase, engineering support during design, construction and installation, and technical support after you open. An extensive global distributor network provides Installation and startup assistance, guidance, and support throughout the life of your project. Tech support is available via distributors, by telephone, equipment manuals, and on-line.

Conveniently located in the Chicagoland area with easy access to two major airports. Call us for a tour of our manufacturing facility.

7083437738